Breakovers add another dimension to trenchless projects, introducing their own quality and construction factors, and resulting risks. After many years of managing projects incorporating breakovers, we’ve observed one simple fact: having all on site aware of the requirements to construct and maintain the breakover within its engineering constraints and practical limitations is the vital ingredient in ensuring a sound breakover and good pipe handling practices – and avoiding kinking, overstressing, and other damage to product pipe and coatings.

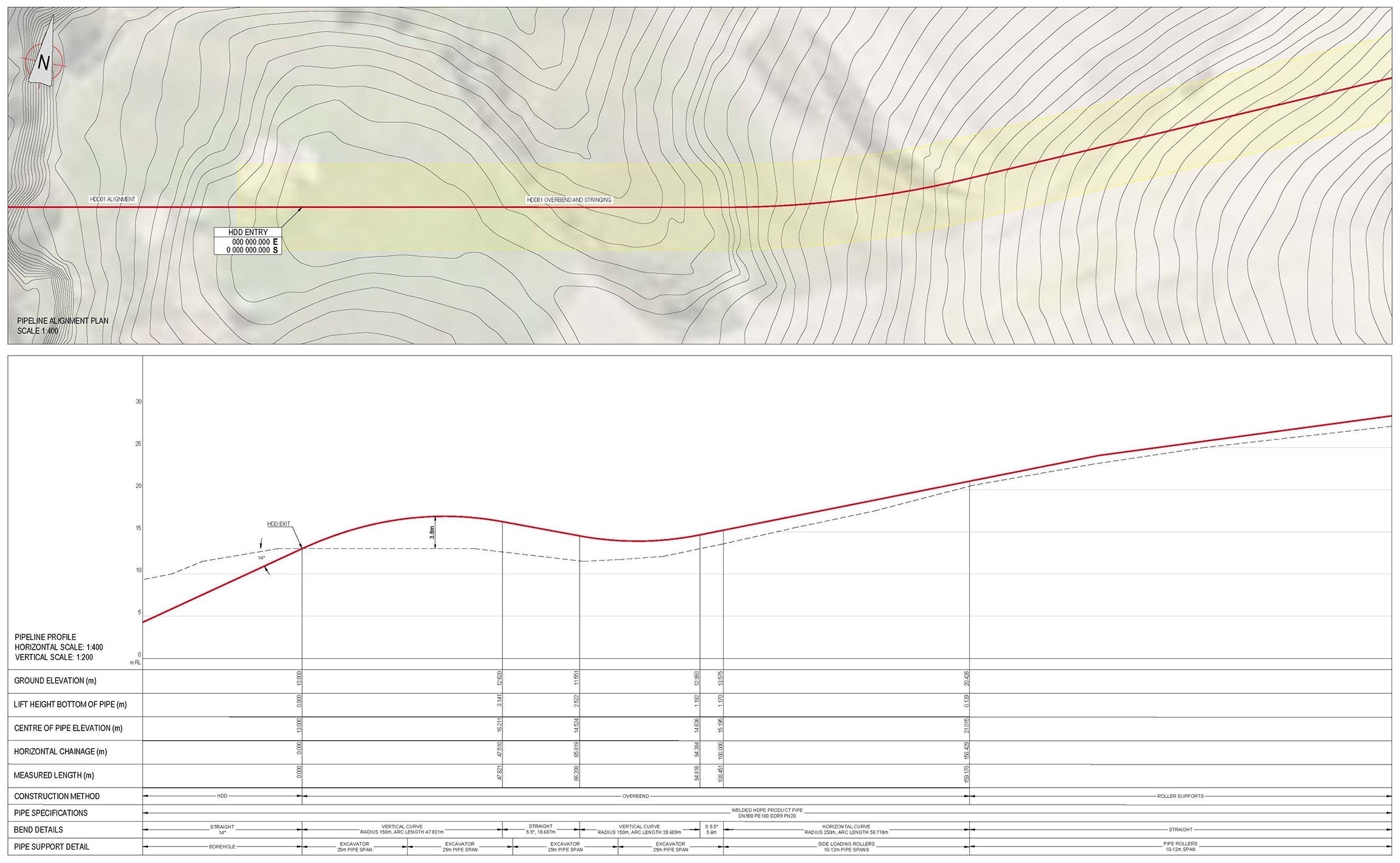

As such, our engineering team has taken that experience and combined it into a straightforward, tried-and-true solution for best practice breakovers: the Breakover Plan. Designed to bridge the gap between engineering and practical handling of breakovers, the breakover plan sets out section-by-section requirements for individual breakovers, tailored precisely to pipe specifications, borehole exit angle, stringing area, site obstacles, and other specific project factors. It sets out all information required to establish the breakover in one document, including pipe supports, plant and equipment; ground and pipe elevation; lift height; chainage; and bend details. Plotted over aerial photographs and in the same format as the HDD profile drawing, the breakover plan is site-ready and designed to be understandable at a glance, to be used as a one-stop guide to achieving the optimal breakover for the project.

Director Col Harris said that mutual understanding between engineers and site personnel is vital in breakover management. “Everybody on a trenchless project needs to be on the same page to ensure breakovers take into consideration not only the engineering constraints of the pipe, but the practical realities of pipe handling, machine operation, and site layout,” he said. “Our breakover plans take both sides into account, ensuring breakovers can be set up and managed in an optimal way for overall project success.”

Col added that the breakover plans have been a long time in the making. “Our engineers have developed and used these breakover plans for many years on site, and we’ve found that they add major value to projects in terms of minimising quality and construction risk, so we’re excited to officially add them to our product range,” he said.

Read more about our new breakover plans here, or if you’d like to organise a breakover plan for your next trenchless project, please get in touch.