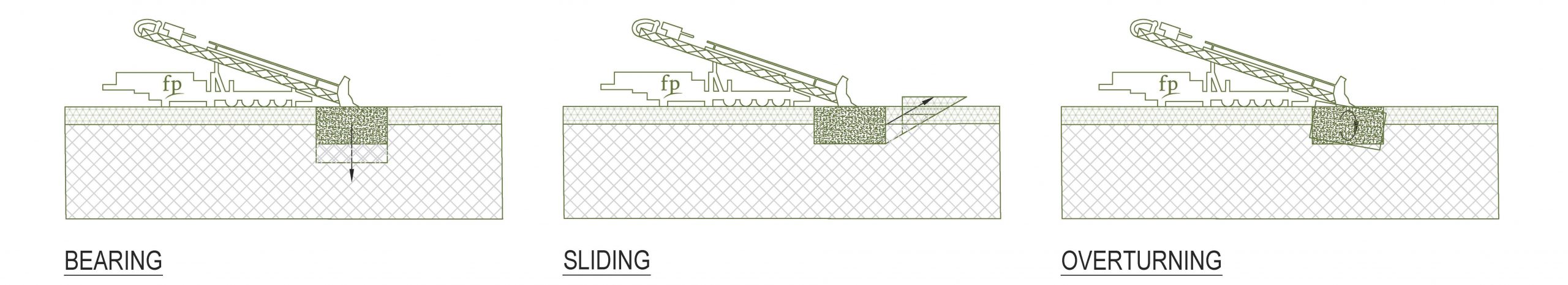

The HDD anchor is a vital foundation of the project – literally. Intended to prevent overturning, sliding, and other unplanned movement of the drill rig, the anchor must be capable of securing the rig while it is subject to the significant forces of drilling, reaming, and pullback.

But how capable is capable? Every HDD project is different: different soil, loads, rigs, site layouts … And although you definitely don’t want to utilise an anchor that is insufficient for project requirements, you also want to avoid overkill – that is, using an anchor that far exceeds requirements (and budget).

In short, HDD anchors are not a one-size-fits-all situation. With this in mind, we’ve designed our HDD Anchor product specifically to reduce these unknowns: to give our clients the peace of mind that their anchor will stand up to requirements, plus the added benefits of being able to plan and budget for the anchor at the earliest point possible.

To create our HDD Anchor product, our team of HDD specialists collects a range of project information, such as geotechnical parameters of surrounding soil; HDD applied loads from thrust and pull; weight of rig, anchor block and other components; proposed anchor dimensions and materials; and site layouts. Detailed calculation and analysis is then completed to determine capability of the HDD anchor, and to provide clear advice on how to ensure it will stand up to the demands of the job.

Presented in a logical, user-friendly document, our HDD Anchor product includes the following:

- Calculations of the forces applied by the HDD rig to the anchor, providing a factor of safety for each failure mechanism

- Assessment of whether the geotechnical properties of the soil are able to withstand the loads, and whether anchor design is appropriate for the proposed loading conditions

- Associated recommendations for anchor suitability

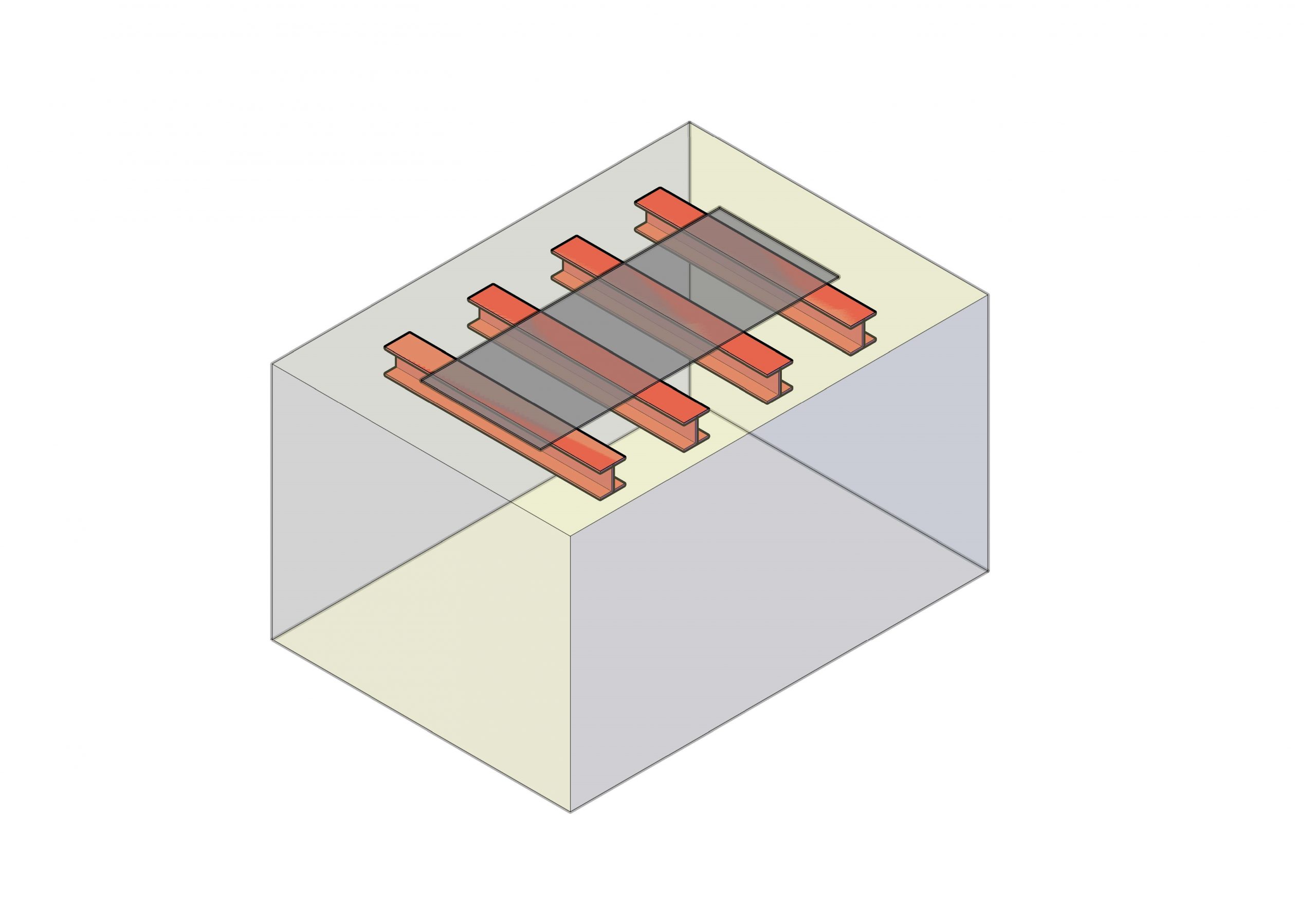

- Anchor drawings, including 2D and isometric 3D views

- Material take off of the proposed anchor, summarising required materials for construction.

In designing our HDD Anchor product, we’ve ensured it is site-practical, not just something that works on paper. As such, it includes contingencies to account for the realities of HDD projects, such as latent conditions, worst case soil, equipment failure, and so on.

Given that HDD anchors face their most significant hurdle during pullback – far past the point of no return, or any opportunity to cost-effectively re-engineer – the benefits of designing anchors appropriately from the start of the project cannot be understated. The HDD Anchor product creates a solid foundation for project success: providing everything our clients need to factor costs for the anchor into the budget, reduce unknowns, and avoid the danger and cost of anchor failure, with confidence.

If you’d like to know more about our HDD Anchor product or any other of our trenchless design products, please visit our products page, or contact us any time.