OUR TRENCHLESS SERVICES

Trenchless Engineering

We provide comprehensive trenchless design and engineering services, with a focus on the most practical, simple, and low impact construction solutions. Our trenchless specialists ensure vital industry engineering factors and challenges are taken into account when producing profile designs. The result: clear, concise, and constructible trenchless engineering.

In order to deliver successful trenchless pipeline projects, risks throughout the various phases of construction must be mitigated. Several engineering products can assist in doing so, ranging from HDD Profile for pilot hole steering, to Hydrofracture analysis for limiting downhole pressures, to torque and drag assessment for reaming operations and the calculation of product pipe Installation forces. Specialised trenchless engineering services provide significant benefits by communicating to stakeholders, contractors and clients the anticipated construction requirements, allowing informed decisions to be made and risks to be minimised.

Our team is highly educated and experienced in the specifications and distinct challenges of trenchless pipeline applications, including in the underground distribution of water, sewer, petroleum, electrical, and telecommunications. We collect reference material from completed trenchless projects worldwide to compare and better test our engineering product range. With the combined knowledge and capabilities from past projects, case studies and complex engineering tools, we are able to produce tailored trenchless engineering solutions efficiently and within your development schedule.

Our engineering solutions are applicable to all types of trenchless crossings, such as:

- Infrastructure crossings

- Environmental waterway crossings

- Ocean outfalls

- Shore approaches.

Additionally, all Future-Proof Solutions designs and calculations are verified by 3rd party software and may be validated by 3rd party nationally registered engineers (RPEQ and NER) on request.

Constructability Review

We can provide thorough assessment of planned trenchless projects, in order to establish a project’s constructability and feasibility, and protect our clients from otherwise unforeseen delays and costs. Utilising a wide range of technology, analytical methods and experience, our team can identify project risk during the design phase, allowing for development of mitigation strategies to maximise success.

Our constructability review services hinge on our team’s position at the forefront of the trenchless industry, combined with a long history of providing successful project outcomes across a variety of pipeline applications. Along with our network of industry consultants, we can provide comprehensive guidance on all aspects of a trenchless project’s delivery, including but not limited to the following:

- Suitability of specialised trenchless equipment

- Correct allocation and use of trenchless downhole tooling

- The most appropriate and tested drilling fluids and quantities for the known geotechnical conditions and methodology

- Pipe material selection and justification for trenchless installation

- Validation of engineering supporting documentation.

By considering customer, statutory, regulatory, and other requirements, balanced with known variables such as geotechnical conditions and site constraints, we can provide clients with a comprehensive suite of constructability documents, such as:

- Construction evaluation reports

- Feasibility studies

- Downhole tooling plan

- Risk assessments and mitigation strategies

- Cost evaluations.

Engaging Future-Proof Solutions to evaluate your trenchless construction project and its risks is the best place to start in ensuring your project is executed on budget and on schedule.

Project Implementation

A successful project requires well-managed project implementation from start to finish. From survey and site establishment to logistics and HSE, the range of critical tasks during the phases of a project require a team of skilled professionals with the experience and know-how to get the job done. Trust our team to provide a foundation to maximise the success of your project.

We assist our clients with project implementation across a wide range of business functions. As project implementation is when the building blocks of a project’s success are created, it is vital that these blocks are laid in a planned and holistic way, ensuring that each aspect complements the next. To do so, we can deliver project implementation services including the following:

- Survey and site establishment

- Subcontractor selection and management

- Full service project management in compliance with PMBOK methodology

- Equipment and materials procurement

- Land and sea-based logistics

- Health, safety and environmental compliance

- Production of HDD as-built drawings.

We have experience in domestic and international projects ranging from simple and straightforward, to multi-discipline and complex. Whether it be short-term or long-term, wide-ranging or targeted, Future-Proof Solutions can provide tailored assistance to meet your requirements and ensure project delivery.

Superintendent Representation

Ensuring the works are executed in line with the contract and specifications is the next key factor for project success – and we can assist with our Superintendent Representation service.

Superintendent Representation is designed to provide project principals with an objective, consultative representative to monitor specification and contract compliance throughout the project. As subject matter specialists, we apply our extensive knowledge of the trenchless process and the individual project, engaging extensively between principal and contractor to facilitate positive outcomes.

Our key point of difference in this service is our approach. While we represent the principal when providing Superintendent Representation services, we prioritise consultation, communication, and cooperation in doing so. This approach has been developed after many years of experience as both project principal and contractor, and the knowledge that respect and collectivity improves outcomes – namely, projects completed on spec, time, and budget.

Superintendent Representation services are tailored to individual client and project needs, but they can include the following:

- Review of design, engineering, and construction methodology

- Design validation

- ITP assessment

- Construction program and milestone monitoring

- Data review and analysis

- Meeting representation

- Variation evaluation

- Other specialist tasks, such as drilling fluid testing as per API recommended practices, as required.

Our Superintendent Representation service allows principal contractors to get the most out of their trenchless projects, by gaining an instant, objective expert in the field. Let us bring our years of experience and our practical, straightforward approach to represent your interests.

Tender Management

An effective tendering process is central to success in trenchless projects. Future-Proof Solutions offers a range of tender management and support options for both tender issuers and respondents, aimed at streamlining and optimising the tender process for the best possible outcomes.

For tender issuers, Future-Proof Solutions offers a range of services, from assistance with single aspects of the tender process, to a full, end-to-end tender facilitation service. Our services include:

- Determining intended project outputs and outcomes

- Determining and delineating intended scope

- Advising issuers on options for HDD design, project methodology, timelines, construction tolerances, scope allocation, and other project variables

- Creation of a suite of fully tailored request for tender documents, including tender details, conditions, scope of work, schedules, and returnables templates

- Tender advertisement, invitation, and release

- Respondent liaison and addressing of questions on issuers’ behalf

- Facilitation of tender briefings and site visits

- Evaluation of tenderers’ submitted returnables

- Recommendation and shortlisting of preferred tenderers

- Award of contract.

We can also offer Issued for Tender designs and many other optional extras to address individual tender and client needs – just get in touch to discuss options.

For tender respondents, we can also offer flexible response and support services, including:

- Tender review and scope determination, ensuring that all scope items in the tender are recognised, allocated, and priced – and potential missing items are identified and addressed

- Attending tender briefings and site visits on respondents’ behalf

- Creation and population of respondents’ returnables, including but not limited to tailored methodology, construction program, cost schedule, bill of quantities, ITP, HSEQ documents, HR and capability documents, and more – all in native, amendable formats

- Tender submission

- Stakeholder liaison

- Assistance with contract review and negotiation.

Our friendly and experienced Projects Team can assist with the tender process as little or as much as required. From support with a handful of documents, to full client consultation, suite of returnables, and client representation, Future-Proof Solutions can lighten the load at tender time.

Site Support

Do you need a reliable resource for addressing HDD project site administration, compliance, testing, or reporting scope? Future-Proof Solutions’ Site Support personnel are here to help.

Our Site Support team supports principal contractors and HDD contractors in ensuring that necessary administration, paperwork, testing, and reporting is completed on time and to optimum standard. Our personnel can assist with the following:

- Daily, weekly, and monthly reporting, including supply of compliant report templates

- Drilling fluid sampling, testing, and on-site laboratory analysis as per API recommended practices, with all required equipment supplied

- HDD project log review, digitisation, and compilation (e.g. mud logs, drill logs, welding logs)

- Environmental material sampling, and end-to-end management of NATA-accredited laboratory analysis

- Facilitation and documentation of pre-start, toolbox, and other meetings

- ITP management

- MDR compilation

- Document and records management

- Stakeholder liaison

- Community engagement

- HSEQ support, including inspections and audits

- Other specialist tasks upon application.

We can also assist clients in ensuring that all contractual project administration, compliance, testing, and reporting scope items are clearly identified and responsibilities allocated, allowing for simplified resourcing, straightforward accountability, and clear deliverables. This process also ensures that clients receive the most suitable, qualified Site Support personnel for individual projects and circumstances.

Our Site Support team are trenchless industry experienced and hold baseline competencies including general construction induction (white card), first aid and CPR, 4WD training, and open drivers’ licence. With an additional mixture of engineering, drafting, auditing, HSEQ, and logistics qualifications and skill sets, Future-Proof Solutions can tailor the right support personnel to your needs.

Contact us to identify and engage the most suitable Site Support personnel for your next project.

OUR HDD PRODUCTS

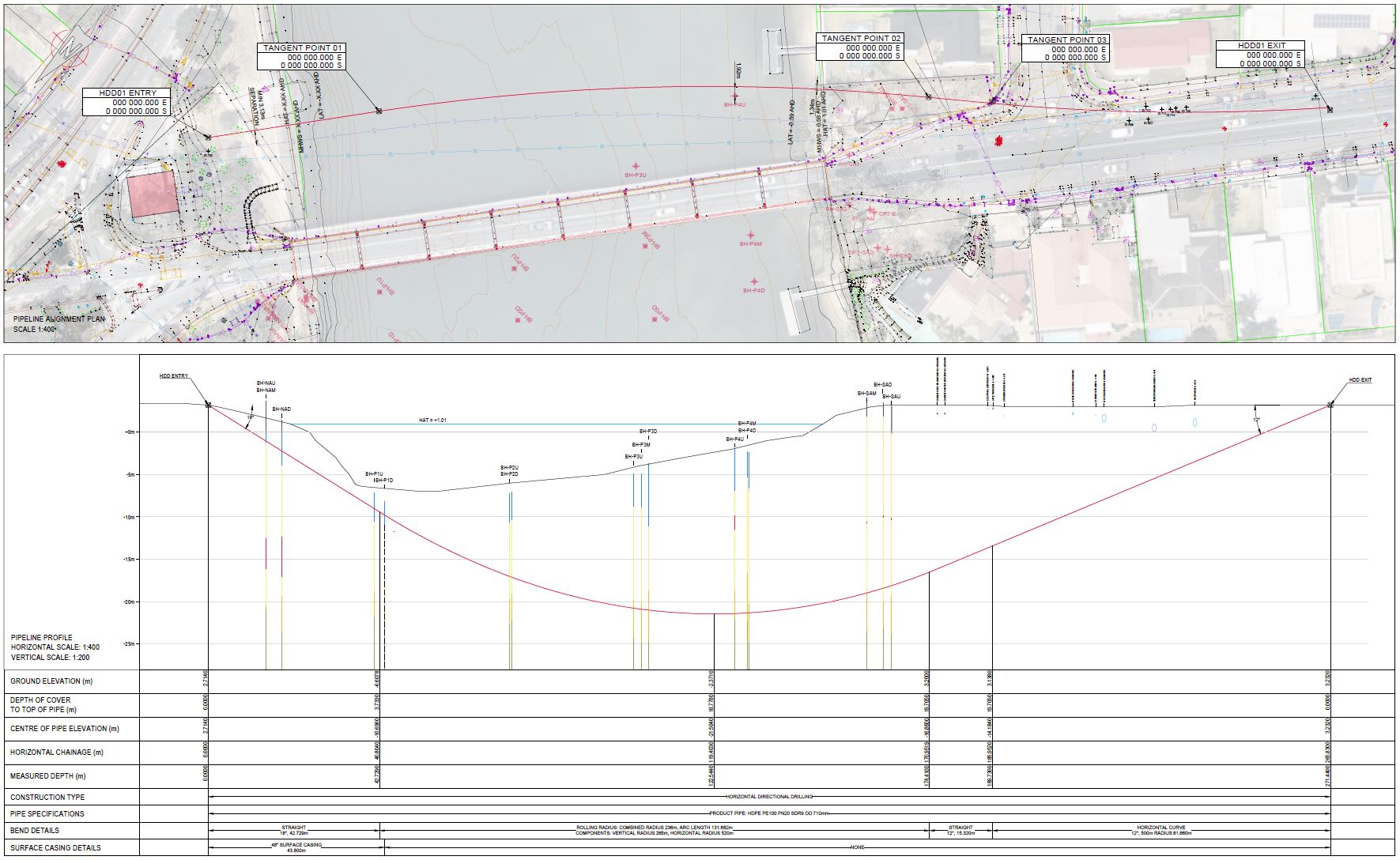

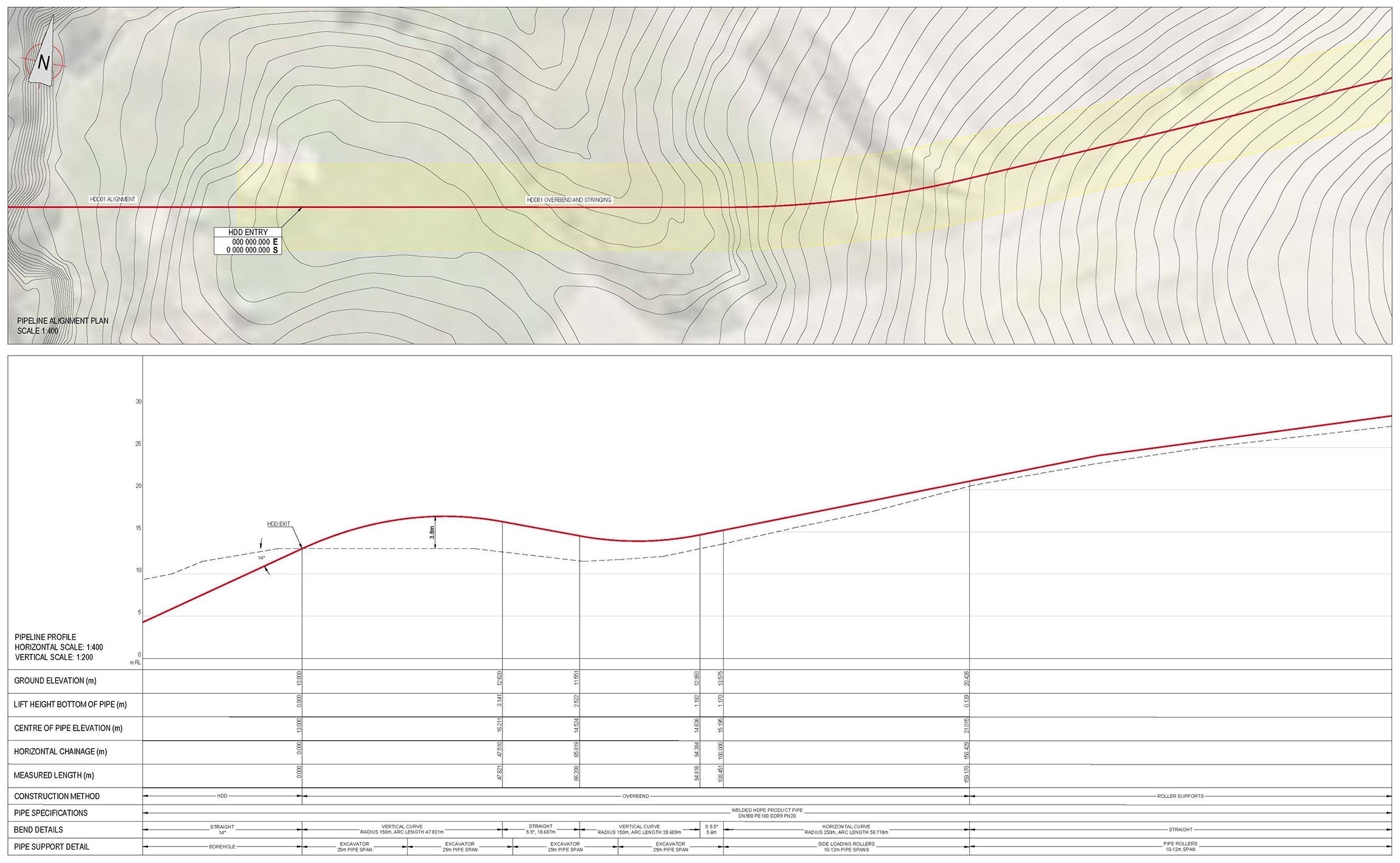

HDD Profile

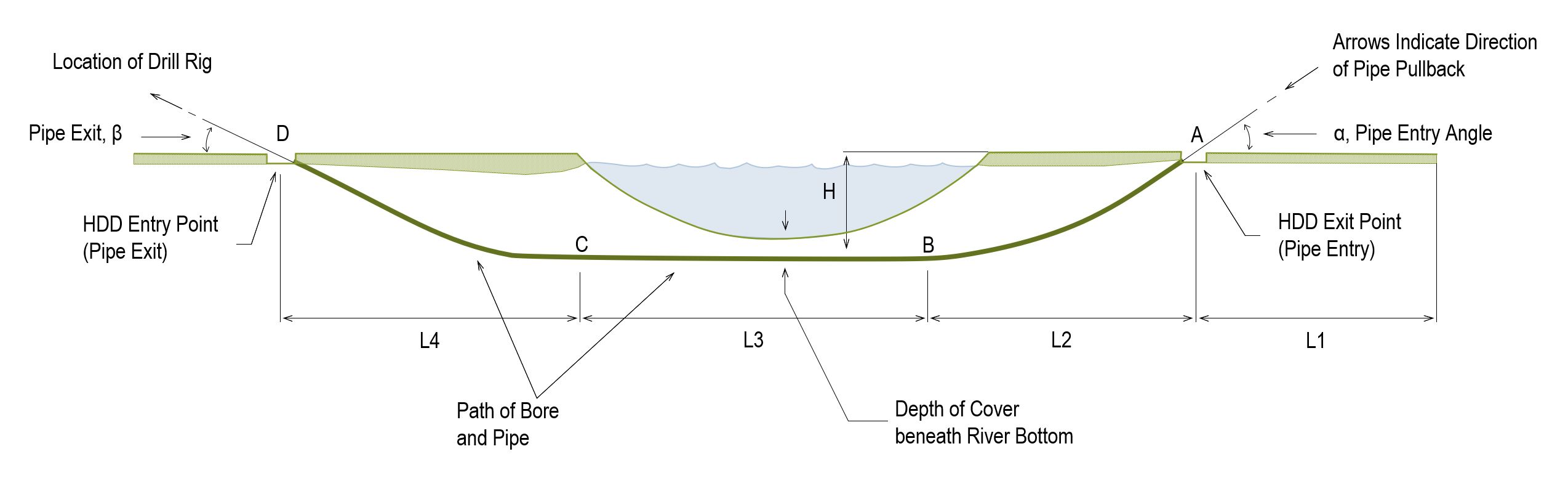

The HDD Profile is a detailed design drawing of the trenchless pipe profile and alignment, including details of where and how the pipeline is to be constructed. The HDD Profile is essential to the trenchless construction process, as it is required for pipe easement approvals, tender preparation, and construction costing, and it provides the basis of further calculations and how to construct the pipe crossing. The drawing is an all-encompassing visual communication and collaboration tool for the trenchless pipeline designed for construction.

The design is prepared by assessing geospatial, geological and topographical information. These inputs include existing services, property boundaries/lease, existing easement constraints, environmentally sensitive areas, and as required bathymetry data.

Entry and exit locations are selected by taking into consideration construction methodology, geotechnical risk and surface area constraints. The profile is then drawn to geometrically minimise impact on existing features and optimise constructability by adjusting bend radii, maximising clearance distances, mitigating compound curves while maintaining suitable depth of cover for the crossing.

The HDD Profile drawing includes:

- The alignment, including:

- Entry and exit coordinates

- Bore hole trajectory in plan view

- Surface data

- Existing services in proximity to the design

- Tangent point locations

- Existing boundaries and easements

- Aerial images

- Geotechnical bore hole locations

- The profile, including:

- Entry and exit angles

- Bore hole trajectory in long section

- Surface elevation

- Existing services crossing the design

- Tangent point locations

- Depth of cover

- Surface water and ground water levels

- Geotechnical bore hole vertical depths

- The design features, such as:

- Ground elevation

- Depth of cover to top of pipe

- Horizontal chainage (2D)

- Measured depth (3D)

- Construction type

- Pipe specification and material

- Bend radii and straight sections

- Surface casing depth

- Grouting depth.

The result is a clear how-to guide for completion of bore hole drilling, steering and final pipeline installation.

For added assurance, HDD Profiles can also be checked against Installation, integrity and Hydrofracture calculations. These optional extras can provide additional information on pipe specification suitability and constructability during the design phase, decreasing uncertainty and minimising project risk in the earliest stages of the project.

Installation

Once the initial HDD Profile has been developed, the selected pipeline material can then be verified for construction. The calculation assesses all forces applied to the product pipe during installation, determining if pipe will be de-formed or de-rated during the process, and to what degree.

The Installation Calculation is primarily based on product pipe specification and HDD Profile. It also includes adjustments for ballasting, friction coefficients, drilling fluid properties, direction of installation, drilling equipment, and fabrication or corrosion allowances, ensuring that the specific trenchless construction methodology and conditions are taken into account.

The installation calculation is performed utilising the above input data and applying these to various peak standards for HDPE and steel pipelines, including the following:

- Australian standards

- Pipeline Research Council International standards

- Det Norske Veritas standards

- American Society for Testing and Materials standards.

The calculations provide an overview of assumptions and expected loads, providing clients with the full picture of force analysis. The calculation provides valuable information on product pipe suitability and assists the construction team to potentially identify downhole issues before they become irreversible. Should the calculations have an unacceptable factor of safety, revisions to the initial design or the product pipe selection can be made and the calculation iterated until an acceptable and constructible solution is developed.

From here, additional complementary products, such as Anchor Block calculation and design, torque and drag calculations, pulling head design, Drilling Fluid Plan, and Site Layouts can be used to further determine and document installation requirements.

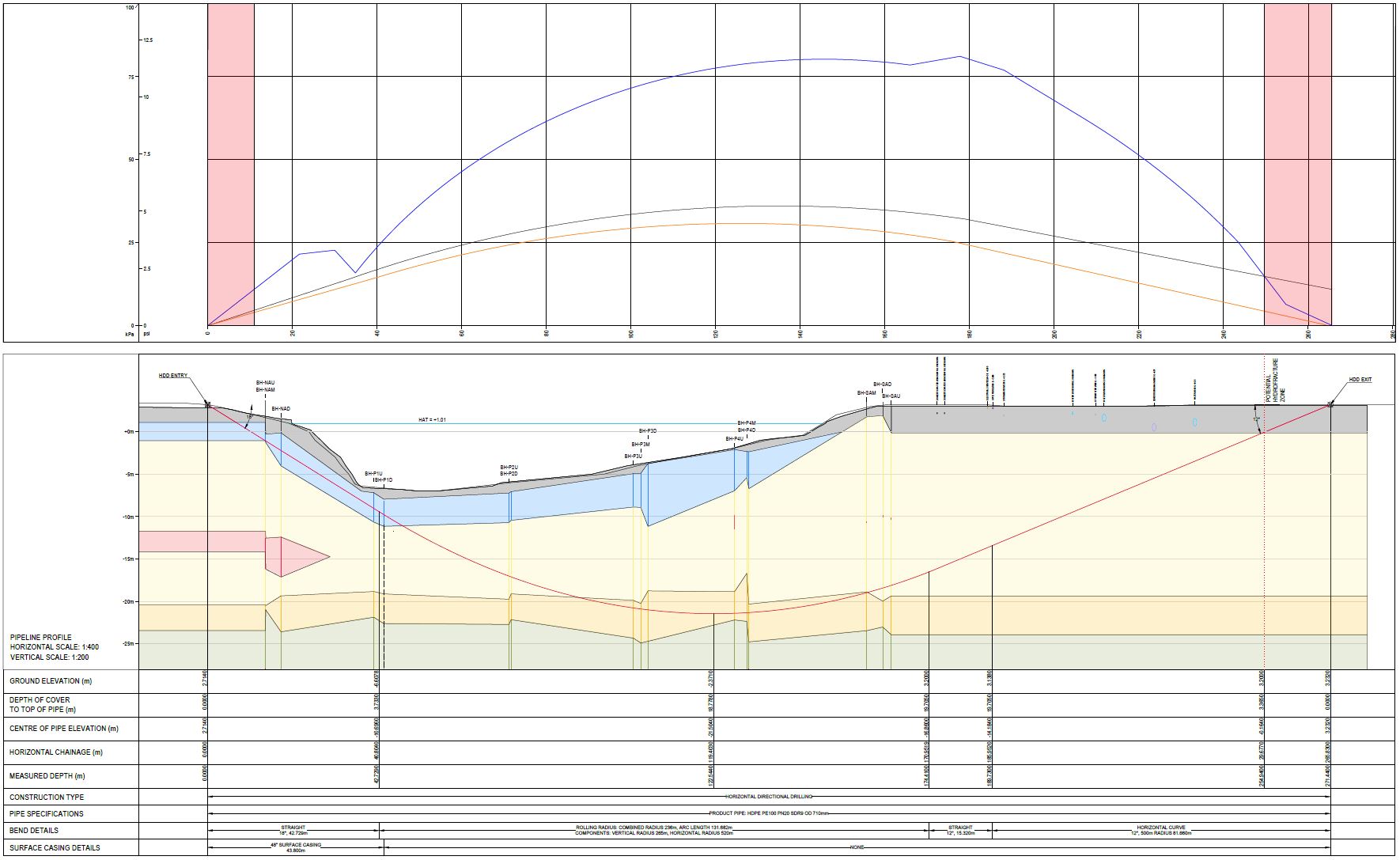

Hydrofracture

Prepare, prevent and plan for the release of fluids to surface with Hydrofracture Analysis. Trenchless construction relies on the pumping of fluid in order to excavate, lubricate and carry cuttings out of the bore hole, and the fluid pumped down hole needs to return to surface via the annular space to prevent pressure accumulation. Static or circulating (pumping) pressure is of utmost importance during drilling, as exceeding the formation strength leads to formation failure (fracture) and fluid leaving the bore hole. The Hydrofracture Analysis calculates overburden pressure, which indicates the maximum that can be pumped while confining fluid within the bore hole, thereby mitigating environmental and pipeline constructability risk.

Inputs to the Hydrofracture Analysis include the HDD Profile, geological information, fluid rheology, and drilling methodology. An interpretation of the geological profile is undertaken to best represent the material along the profile, with conservative estimates made so the model is based on worst case scenario. The cavity expansion model is used to calculate the overburden pressure, and the Bingham plastic or power law model are used to calculate expected drilling fluid pressures. A graphed comparison of these pressures over the length of the borehole is used to assess whether the fluid is contained in the borehole, if circulating pressure is below overburden pressure, or whether fluid will fracture the formation, pressurising into the surrounding soil or potentially releasing to surface.

The Hydrofracture Analysis communicates the risks and may be utilised by the construction team to ensure constructability is measured against risk exposure. To reduce risk, either the overburden pressure can be increased or the drilling fluid pressure reduced via one or more measures, as follows:

- Design amendments

- Increasing depth of cover

- Increasing entry and exit angles

- Increasing depth under waterways

- Relocating entry or exit location

- Targeting stronger geological layers

- Increasing depth of cover

- Mechanical devices

- Installing surface casing

- Utilising pressure monitoring tools

- Methodology amendments

- Changing preferred entry and exit orientation

- Limiting maximum pump rate

- Changing tooling size

- Amending fluid rheology design

Products such as methodology and Drilling Fluid Analysis can further complement Hydrofracture Analysis.

Site Layouts

Site Layouts are a vital planning and constructability tool that depict the plant and equipment positioning for the completion of trenchless works. This includes the entry and exit layouts, breakover alignments, indicative noise levels, and pipe string preparation and welding areas.

Site Layouts combine site conditions from several sources. They are initially drafted to include the following:

- Trenchless HDD Profile and alignment detail

- Existing property and site boundaries

- Environmental impact areas

- Surveyed features, including trees, light poles, road edges, etcetera

- Pipeline easements

- Surveyed existing services

- High quality aerial imagery.

Once site conditions are clearly understood and marked, positioning of the trenchless project equipment can be undertaken to validate the proposed HDD profile and construction method.

To produce an effective site layout, site boundaries are plotted on a selected survey grid, and equipment is orientated along the alignment, taking into account available site constraints and specific equipment deemed necessary for construction. Site layouts are designed to maximise project practicality and site safety whilst minimising environmental and community impacts, and additional considerations such as rig design, capacity and loading orientations may result in requirements for further review and amendment of site layouts as an iterative process. The site layout constructability assessment may also indicate the need for amendment to the allocated temporary or permanent land tenure areas.

The resulting site layouts include detail on the following:

- Construction pad areas

- Site access tracks

- Temporary construction works, including Anchor Block , sheet piling, etcetera

- Positioned trenchless equipment

- Environmental impacts and controls.

Additional detail can also be included on request, such as locations of fire extinguishers, first aid kits, spill kits, hazardous chemical storage, site muster points and site signage, as per requirements of AS 3745:2010 Planning for Emergencies in Facilities. A georeferenced site layout export may also be made available to surveyors for site mark-out during planning or establishment phases.

Site layouts can be further complemented by Anchor Block and construction methodology documents as optional extras.

Fluid Plan

Drilling fluid is a vital component of every HDD Project. During drilling operations, a viscous fluid is pumped through the drill string, out the downhole tooling and into the borehole annulus. The drilling fluid is used to excavate, stabilise, lubricate and carry cuttings out of the bore hole. The Drilling Fluid Plan is a planning and operational tool that provides concise guidelines to maintain target rheological properties and estimate required waste/resources.

Detailed planning and assessment are required to effectively develop the drilling fluid plan. In order to provide recommendations to achieve optimum fluid, operations, and borehole performance, an evaluation of drilling methodology including product pipe sizing, downhole tooling, surface equipment and pumping variables is undertaken.

A Future-Proof Solutions Drilling Fluid Plan is tailored to the variables of your project and provides a holistic view of recommended drilling fluid requirements, including:

- A summary of project variables and assumptions

- Nominated product pipe, borehole and pumping details

- A summary of planned drilling passes

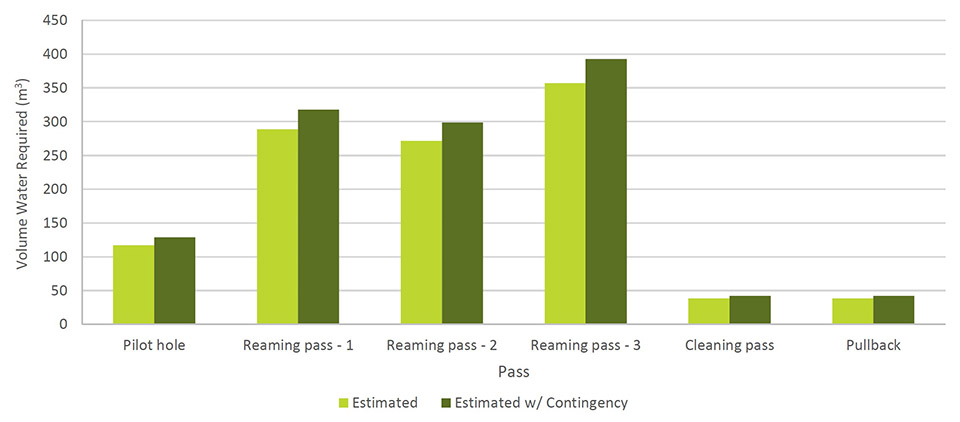

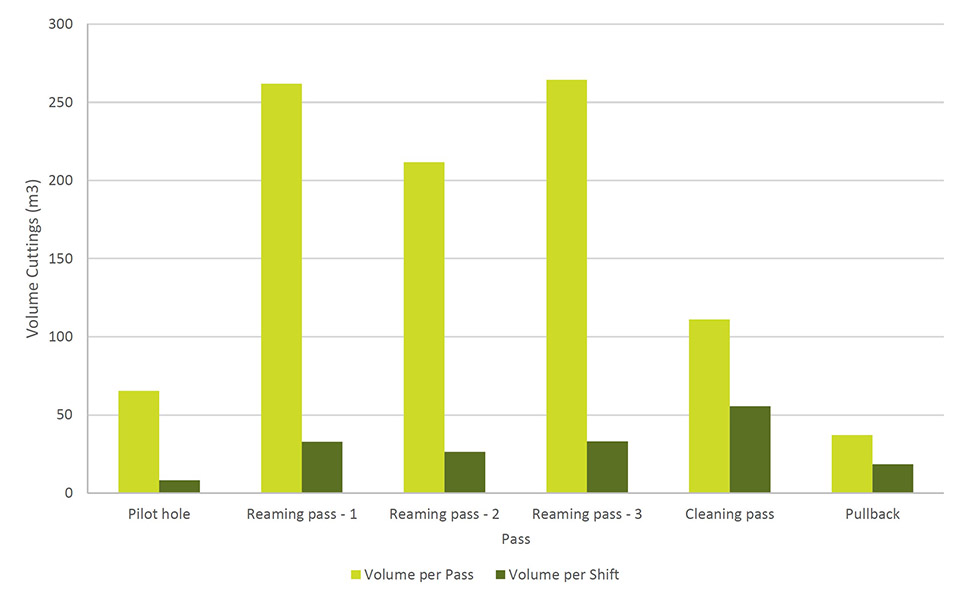

- Calculation of drilling fluid volumes for each pass including:

- Borehole and makeup volume

- Permeation volume: fluid seeping into formation to seal the borehole and forming a filter cake

- Surface recycling system: tank capacity and screening losses

- Estimated total volumes for each pass

- A detailed fluid program setting out the following:

- Target fluid properties

- Specific primary and contingency additive products

- Buoyancy check for recommended pullback fluid density

- A comprehensive resource management program estimating:

- Water requirements

- Cutting production rates and disposal volumes for each pass

- Drilling fluid displacement during product pipe installation

- An optional contingency assessment can be produced for projects where a closed system cannot be maintained, and fluid is not recycled.

Drilling fluid properties impact downhole pressures and buoyancy. These are explored further in additional products, Hydrofracture and Installation.

Read more about how our Drilling Fluid Plan product can benefit your project here.

Breakover Plan

Pipe handling is an essential but high-risk activity during the construction of any trenched or trenchless pipeline. Breakovers – also known as overbends – are necessary when a long string of pipe is required to be moved or lifted into an arch in order to be installed.

Breakovers have the potential to introduce a variety of additional quality and construction risks which must be mitigated to ensure that the pipeline is installed without undue damage to the pipe or risks to constructability. By adequately planning and designing a breakover, the balance between material elasticity, stiffness, and strength can be managed to avoid overstressing, kinking or damaging product pipe and its coating as it is lifted, pulled and installed into the drilled hole.

To establish a Future-Proof Solutions Breakover Plan, initial breakover designs are created, taking into account pipe specifications, construction methodology and profile and alignment factors, such as borehole exit angle, minimum pipe bend radius, available stringing area and above ground obstacles. A comprehensive, site-ready Breakover Plan drawing is then finalised, establishing the pipe and equipment positioning while complying with known engineering, methodology and site requirements.

Plotted over aerial photographs and continuing from the HDD Profile drawing, the Breakover Plan sets out section-by-section information including:

- Ground elevation

- Pipe elevation

- Lift height

- Chainage

- Bend details

- Pipe supports, plant, and equipment.

The Breakover Plan provides a clear and straightforward guide to establishing the breakover, while ensuring that quality and construction risks are adequately mitigated. The Breakover Plan is best considered in combination with the HDD Profile, Site Layouts and Execution Summary for complete trenchless methodology.

Read more about how our Breakover Plan product can benefit your project here.

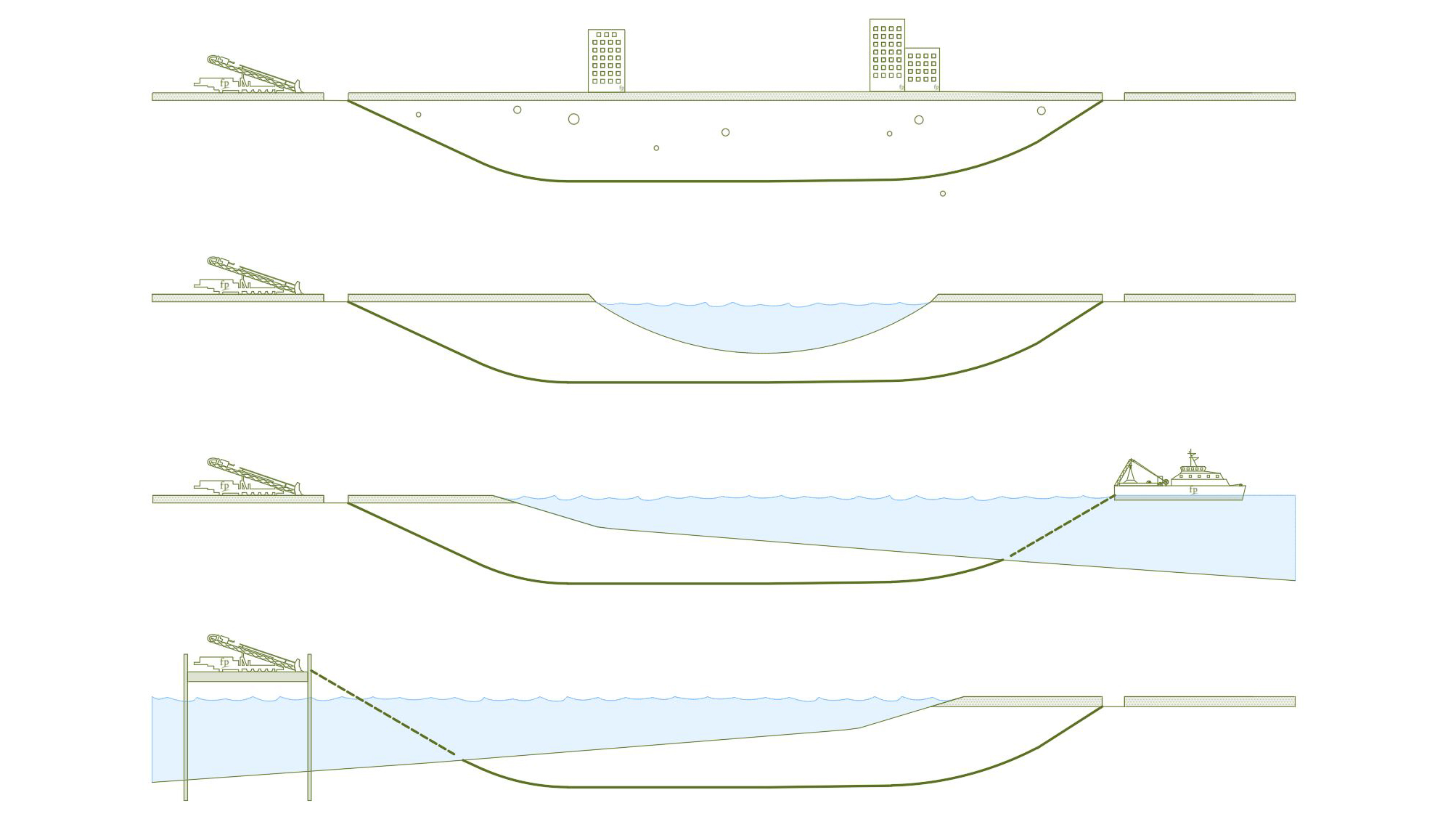

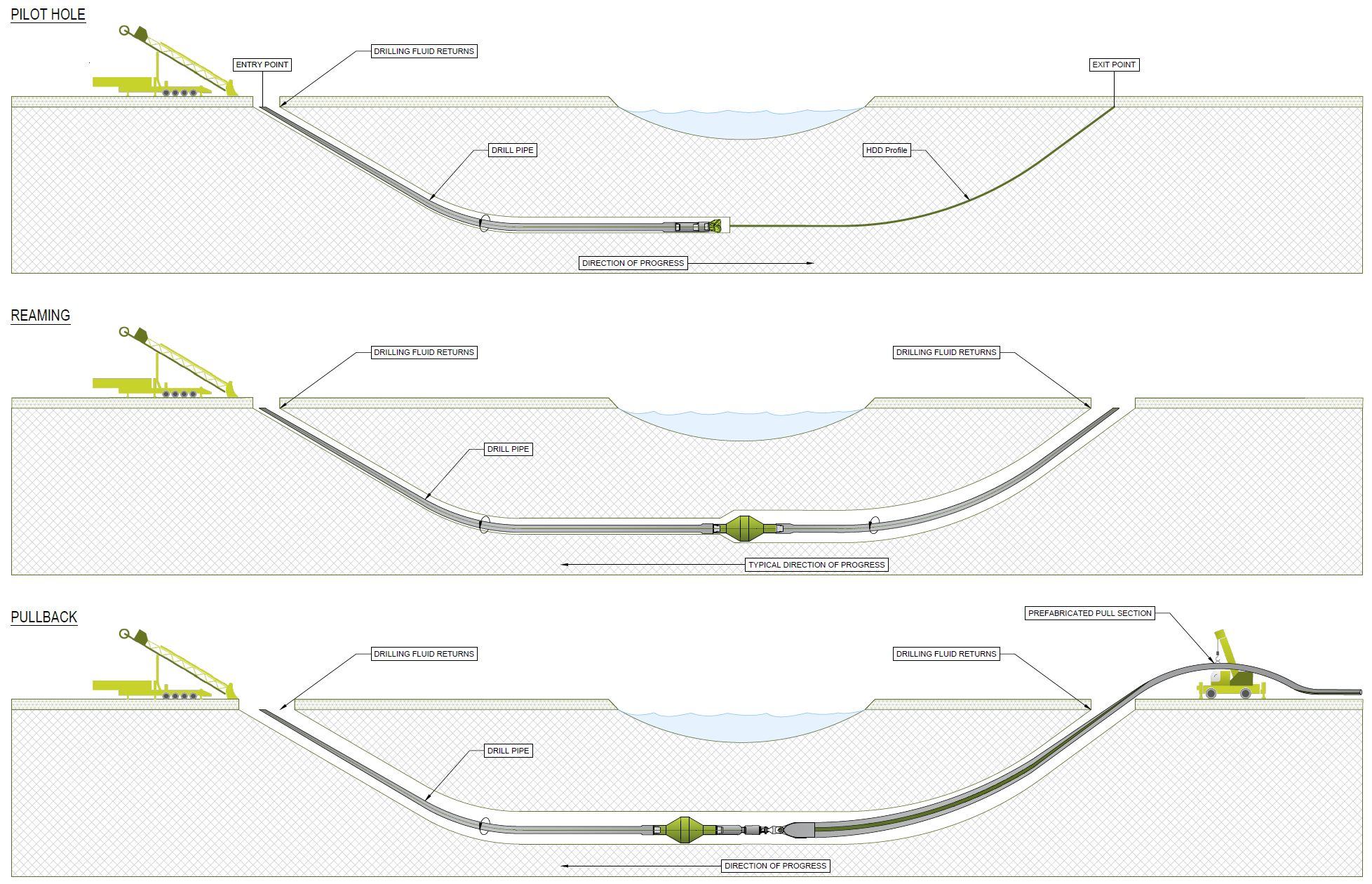

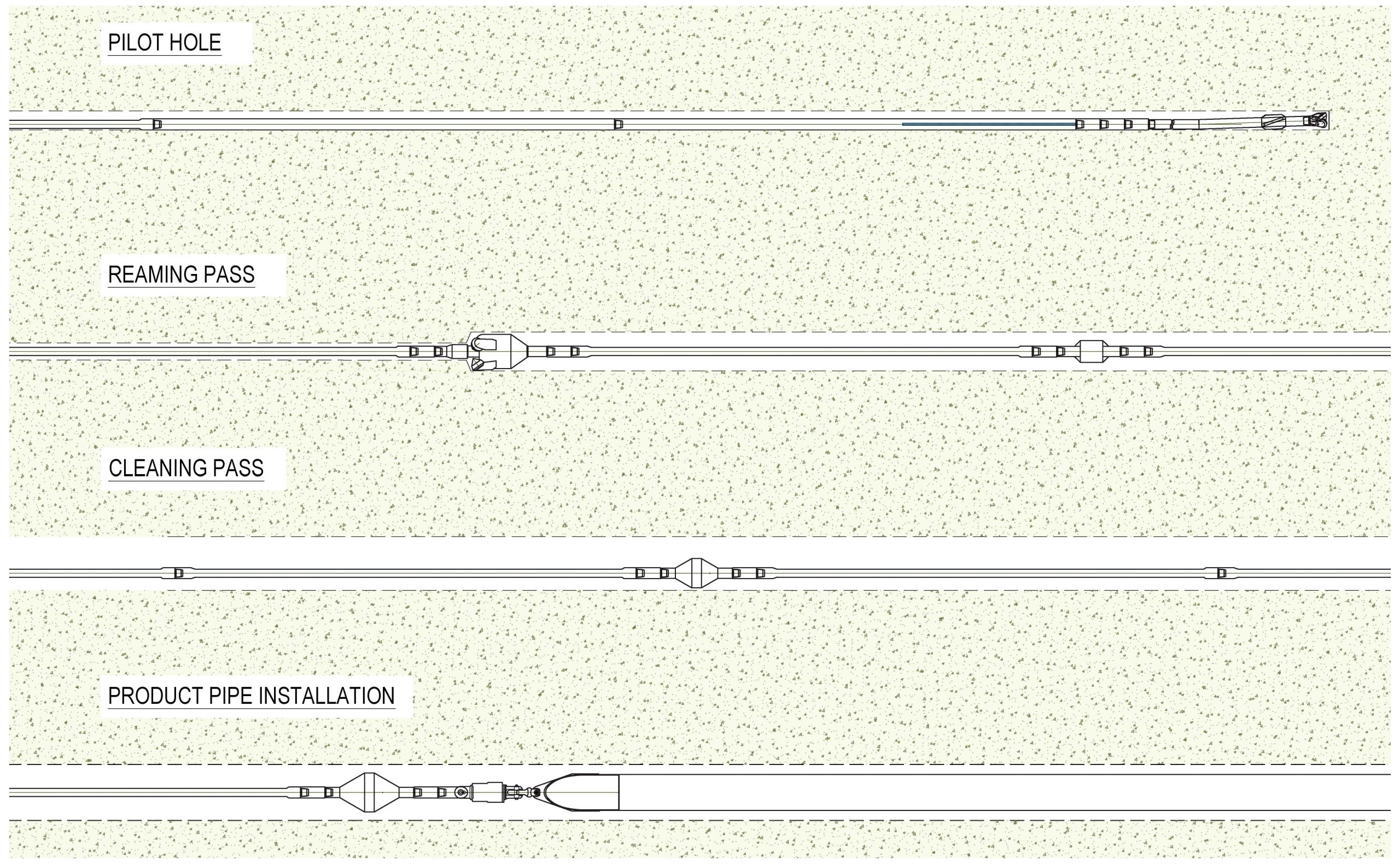

Execution Summary

Trenchless project methodologies can be difficult to communicate both on site and to project stakeholders, due to the majority of activities occurring underground. To solve this problem, our Engineering Team has developed the Execution Summary: a logical, straightforward pictorial illustration of each step of the trenchless project methodology from start to finish.

To develop the Execution Summary, our Team of HDD Specialists reviews relevant project inputs, such as the HDD Profile, Site Layouts, environmental constraints, proposed equipment, and geotechnical conditions.

These inputs and related project risks are then assessed, streamlined, and optimised to determine the best suited project methodology. A concise series of drawings of each step of the project in chronological order is produced, detailing the processes and equipment to be utilised to execute each stage of the trenchless methodology. Depending on the project, these may include:

- Surface casing (also known as conductor casing) installation via hammer or wash over methods

- Establishment of entry and exit sites

- Pilot drilling and borehole enlarging reaming passes

- Supplementary passes, including drill pipe tripping and borehole conditioning

- Marine interface operations

- Product pipe welding

- Product pipe installation

- Testing, pigging, and gauging.

The result is the Execution Summary: a one-stop, straightforward visual representation of the project methodology from start to finish, which can be easily communicated and understood by not only project personnel, but by key project stakeholders such as clients, subcontractors, and the wider community.

As well as being an effective way of communicating the overall project, the Execution Summary streamlines the planning and production of other key project documents, such as project execution plan, project schedule and budget. Using the Execution Summary as a guide, project schedules can be produced in logical, chronological order, including rate of completion, task durations and rate of penetration, and cost estimation and production of the project budget can be completed simultaneously.

Read more about how our Execution Summary product can benefit your project here.

HDD Anchor

The HDD anchor is used to secure the rig in place on trenchless projects and provide resistance to forces during drilling, reaming, and pullback. HDD anchor design is crucial in preventing overturn, sliding, or anchor failure, and must address various factors to be suitable for project operations. We’ve designed our HDD Anchor product specifically to ensure all information is considered and the anchor is designed correctly, for maximum project success.

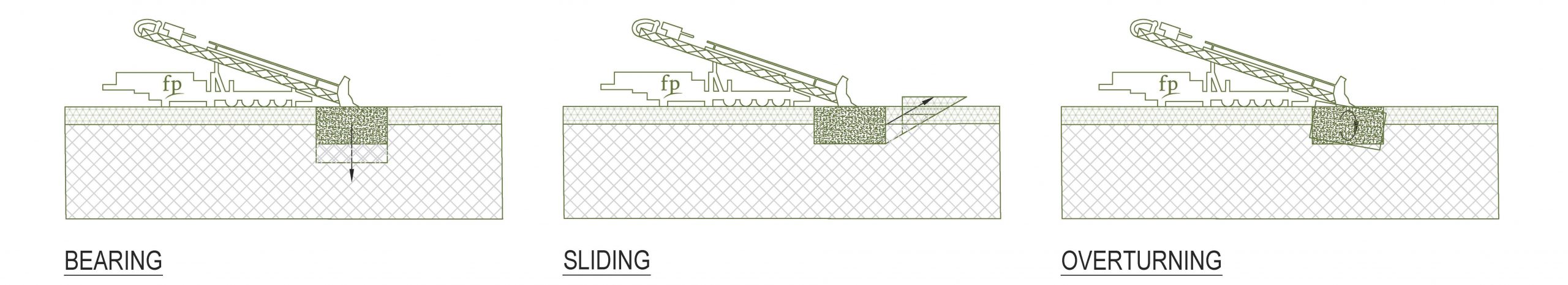

To complete HDD anchor design, we gather information including the geotechnical parameters of surrounding soil; HDD applied loads from thrust and pull; weight of rig and other plant and equipment; proposed anchor dimensions and materials; and Site Layout. Detailed analysis is then completed as such:

- Safety factors from AS5100.3 are applied to increase applied loads and reduce geotechnical strength for worst case analysis

- Passive resistance forces are calculated to determine how much effective earth pressure the soil can exert on the anchor

- Applicable failure criteria are analysed using all forces to determine if the anchor will fail under ultimate bearing, sliding or overturning mechanisms

- Diagrams of failure mechanisms are produced.

The HDD Anchor product is then finalised to include:

- Calculations of forces applied by the HDD rig to the anchor, providing a factor of safety for each failure mechanism, including reduction factors

- Assessment of whether soil properties are sufficient to withstand loads, and whether the anchor design is appropriate for the conditions

- Recommendations for anchor suitability

- Anchor drawings, including isometric 3D and 2D views

- Material take off for the proposed anchor, summarising required materials for construction.

By designing HDD anchors to be suitable from the beginning of the project, major incidents associated with anchor failure can be prevented, and negative impacts on trenchless projects can be avoided entirely.

Read more about how our HDD Anchor product can benefit your project here.

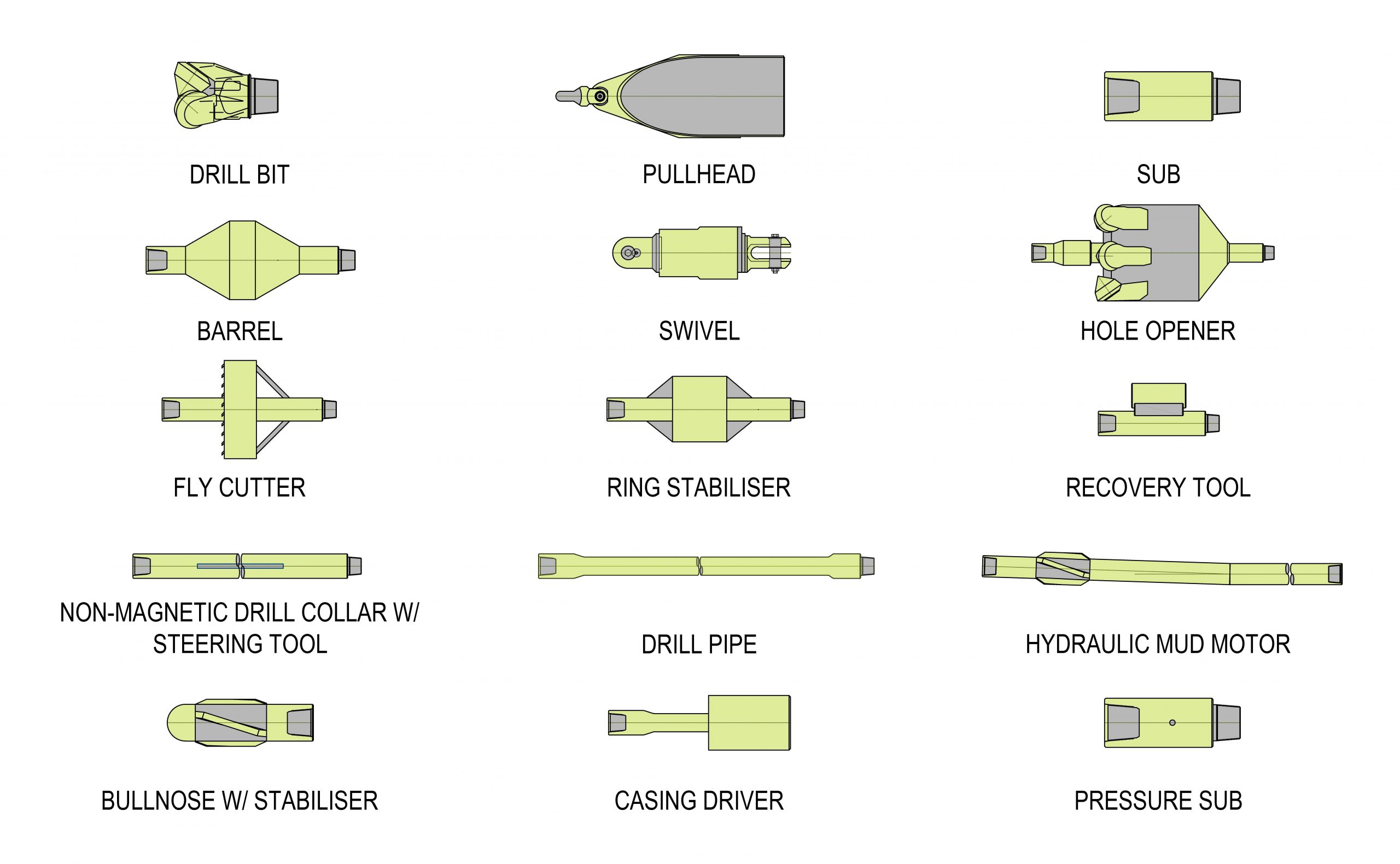

BHA Summary

Using the right tools for the job is vital in HDD, but particularly in relation to downhole tooling, or bottom hole assemblies (BHAs). Selection of fit-for-purpose cutting tools, stabilisers, subs, hydraulic motors, and other threaded tools is crucial in ensuring each pass achieves its intended purpose safely, effectively, and economically.

We’ve designed our BHA Summary product to streamline the process of planning and assessing downhole tooling, as well as selecting and clearly communicating the best tooling for each trenchless engineering project. To do so, our HDD specialist engineers first review the project parameters, planned methodology and expected loading conditions, and consider aspects such as:

- Geotechnical conditions

- Crossing lengths and radii

- Required borehole size, pass sizes, and methodology

- Project equipment, such as rigs, pumps, and available tooling

- Torque, tensile, compression, and bending loads.

Taking this information into account, a detailed drawing schematic diagram is produced to illustrate optimal tooling to achieve the proposed methodology, as well as additional equipment that needs to be purchased.

Straightforward and visual in nature, the BHA Summary is useful in effectively communicating vital tooling information in a step-by-step way to a range of stakeholders. It also provides clarity for tooling, costing, and resource planning during project tender and design stages, allowing for more effective project planning and integration – especially if used in conjunction with our Execution Summary and/or Torque and Drag Calculation products.

Read more about how a BHA Summary can benefit your next trenchless project here.

Cuttings Screening

Potential site contamination is a significant environmental risk to all construction projects. HDD construction generally involves the use of an environmentally neutral water-based drilling fluid to return excavated cuttings from the bore hole back to surface. Both the drilling fluid and the cuttings need to be disposed of at various stages of the works. A Cuttings Screening Report tests environmental samples taken from site. It can confirm construction waste compliance with waste classification limits and be used to determine whether contaminants are present in the drilling fluid or in the encountered stratum. The composition of this waste, and its chemical properties, dictates the disposal classification of the material, its potential environmental impact and where it can be disposed of.

The Cuttings Screening process includes material sampling on site, testing at a NATA-certified laboratory, and a detailed report on the material’s chemical and metal composition. The composition is then assessed against the relevant Legislation or Project specifications to determine compliance status with regulatory waste classification levels.

The sampling process and the detailed report can easily be adopted for additional environmental monitoring activities relevant to a HDD construction site, such as gas identification, pre-existing ground contaminant verification, and water quality monitoring.

The result is a clearer understanding of environmental compliance for any HDD project.

A Cuttings Screening Report complements such products as Drilling Fluid Plan and Hydrofracture Analysis.

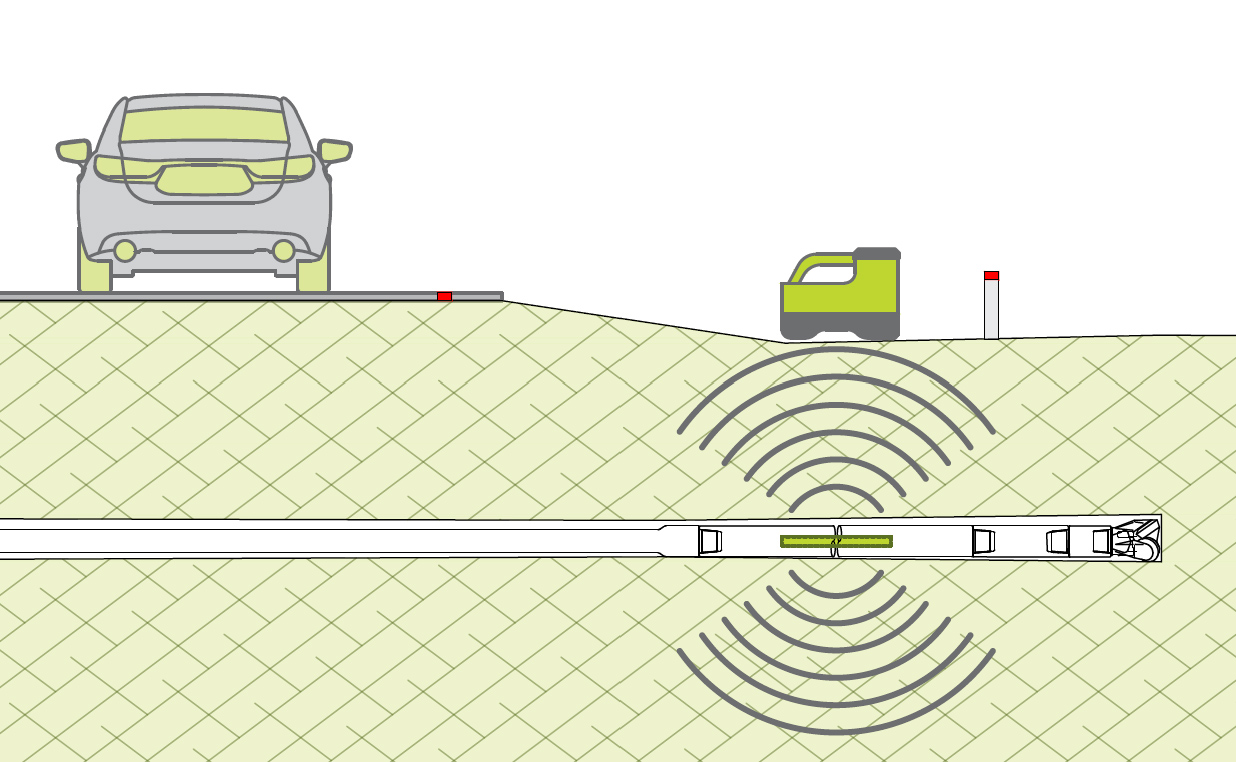

Drill Plan

One of the main difficulties when drilling a prescribed HDD bore arises from controlling the slender downhole tooling during its interaction with the layered stratum. Poor, varied or unexpected ground conditions can cause the drill bit to stray off the design, increasing risk potential which can result in unplanned, costly outcomes for the contractor. Magnetic, gravity and gyroscopic sensors are available to assist steering for HDD construction projects.

A ‘walkover’ system is a cost-effective methodology for monitoring both the depth and direction of a horizontal drill; providing real-time feedback to the driller to enable constant adjustment to the drilling direction. Future-Proof Solutions’ Drill Plan has been developed with this methodology in mind.

This Plan takes into account the BHA tooling, sonde position and breaks the HDD design into a rod-by-rod plan, providing navigational measurements specific to the HDD bore including:

- Rod number

- 2D chainage

- Measured depth

- Depth of cover

- Inclination

- Surface level

- Elevation relative to datum

While drilling is underway the drilling contractor can easily compare their real-time positioning data to the Drill Plan and adjustments can be quickly made where required to realign with the design and deliver a conforming bore.

To assist with the final as-built, the Plan also includes a section for the contractor to log their real-time data obtained during their steering ‘walk-over’.

A comparison of the actual versus the planned design is provided as part of the Profile & Alignment product engagement.

HDD Pullhead

The HDD Pullhead is a make-or-break item for every HDD borehole. Used as an adaptor between the rig and the product pipe, the HDD Pullhead is subject to unique – and considerable – forces during installation. And as every pipe pull is unique, so are its forces: while a pullhead may be sufficient for one pullback, it may be in danger of overstress and failure for the next.

We’ve designed our HDD Pullhead product to remove the guesswork and the risk. First, our HDD specialist engineers review proposed pullhead information, and we complete a series of calculations for each component of the pullhead. In doing so, we take into account the following and more:

- Material types, specifications, and grades: can be completed for both HDPE and steel pipes

- Componentry types and dimensions

- Connection type

- Open or closed construction type

- Reduced cross sectional area and failure plane for drilled holes

- Information from complementary products, such as the Installation Calculation

From here, we provide a detailed HDD Pullhead report outlining material utilisation factors, percentage of strength used, and the overall maximum pull load that can be applied to the pullhead during installation, providing the information needed to avoid excessive pullhead stress and – worst case scenario – failure.

Every calculation in our HDD Pullhead product is fully tailored to the individual pullhead, removing assumptions and risks in what can otherwise be a high-risk area of the project. Inclusions can be fully customised to client needs: we can incorporate pullhead fabrication drawings or other custom inclusions to meet project requirements. Additionally, the HDD Pullhead product can be supplied in conjunction with the BHA Summary for an all-round picture of requirements for project tooling and downhole componentry.

Contact us for a sample HDD Pullhead report or to find out more.

Settlement Analysis

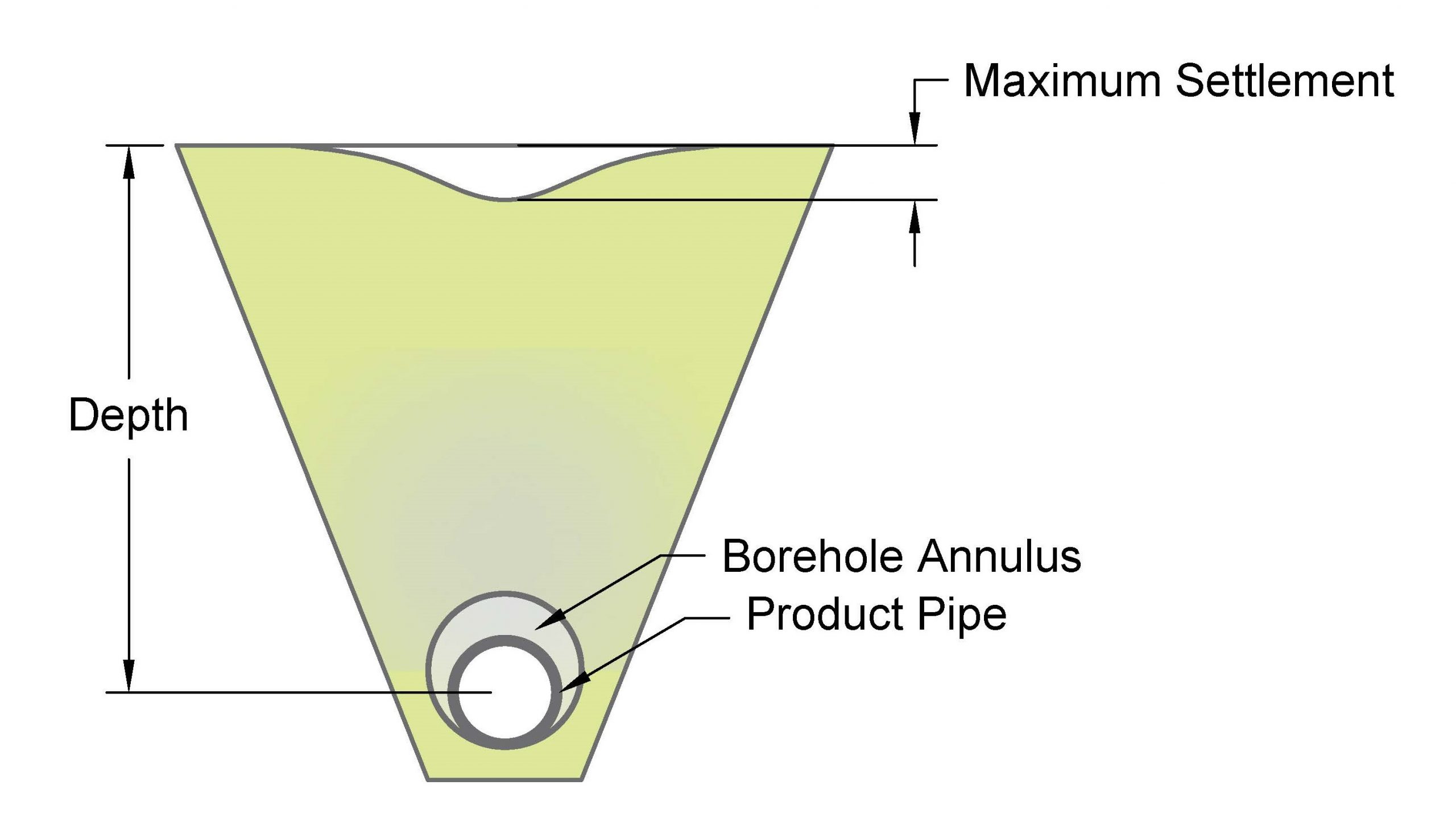

HDD and other trenchless methods are commonly used to install pipelines under roads, railways, and other sensitive areas. The low-impact nature of trenchless installation is one of its greatest strengths – allowing vital pipelines to be placed with minimal disturbance and interruption at surface level.

However, many types of infrastructure are particularly sensitive to surface subsidence – also known as “settlement” – and detailed calculations must be completed to predict the long-term impact of settlement on the ground surface above and adjacent to the installed pipeline. In these situations, Future-Proof Solutions’ Settlement Analysis product can help.

To complete a Settlement Analysis, our Engineering Team reviews project-specific data, such as geotechnical information, pipeline depth of cover, pipe leave state, and product pipe and borehole sizes. Then, after assessing the geotechnical layers for points of interest, settlement calculations are performed based on Gaussian distribution curves.

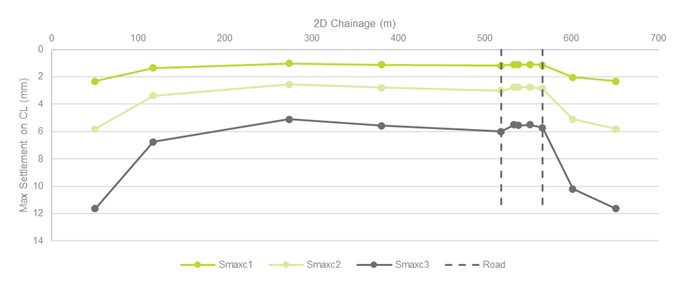

From here, settlement graphs are generated to illustrate information including:

- The maximum settlement over the borehole centreline

- How the settlement tapers laterally

- Maximum settlement directly over the length of the pipeline, for overall assessment.

Multiple cases are considered and illustrated in each graph – including annuluses which are empty, filled with drilling fluid, drilled to best practice or grouted – in order to compare settlement risk for the applicable scenarios.

Our Settlement Analysis products illustrate settlement risk in a clear, uncomplicated manner, accounting for the specifics of the individual project, method, and pipe to ensure maximum accuracy. They allow our clients to be fully informed on settlement risk and the most beneficial option for the individual pipeline, as well as assisting in gaining pre-project pipeline construction approvals.

Contact us to find out more about our Settlement Analysis product.